“Our ammonia engine is the end of EVs”

- AeroDrive Venture

- June 24, 2024

- Category : Automotive

A new charismatic topic in recent times is the ‘Ammonia Engine’. Engines are mainly used to run various types of machinery, such as cars and aircraft. Traditionally, gasoline engines have been predominantly used. More recently, electric vehicles (EVs) have emerged as a new alternative. However, both gasoline and EVs have environmental drawbacks; gasoline engines produce significant amounts of carbon dioxide, and the production and disposal of batteries for EVs can also have negative environmental impacts.

Recently, the CEO of Toyota surprised everyone by stating, “Our ammonia engine is the end of EVs.” This statement has become a hot topic. But is this concept entirely new, or has it been considered before? This blog will cover all aspects of the ammonia engine.

History

Ammonia (NH₃) was first synthesized in 1909 by the German chemist Fritz Haber through the Haber-Bosch process, which allowed for the mass production of ammonia from nitrogen and hydrogen gases. This revolutionary method initially transformed agriculture by enabling the creation of synthetic fertilizers, significantly boosting food production worldwide.

Following its success in agriculture, ammonia saw limited use in other fields initially. During World War II, Belgium used ammonia as an alternative fuel for buses due to gasoline shortages, showcasing its potential as a vehicle fuel. However, post-war, its application remained mostly experimental and confined to industrial uses, as it was difficult to handle and created pollution.

The concept of using ammonia as an engine fuel re-emerged with increased interest in sustainable energy sources. Recently, the focus on reducing carbon emissions has led to renewed interest in ammonia engines. Significant developments include efforts in marine engines and the notable unveiling of a prototype ammonia-powered engine by Toyota and China’s Guangzhou Automobile Group Co. (GAC) in June 2024. This engine aims to significantly reduce carbon emissions, marking a potential shift towards ammonia as a viable alternative fuel for the future.

How Ammonia Engine Works

In a petrol engine, a mixture of air and fuel enters the cylinder. When this mixture is fully compressed, the spark plug ignites it. This explosion pushes the piston down, driving the crankshaft, which converts this motion into rotational energy to power the vehicle. The camshaft controls the opening and closing of the intake and exhaust valves, synchronizing with the piston’s movements. The exhaust gases are expelled through the exhaust system.

In a diesel engine, only air is drawn into the cylinder and compressed to a high pressure and temperature.

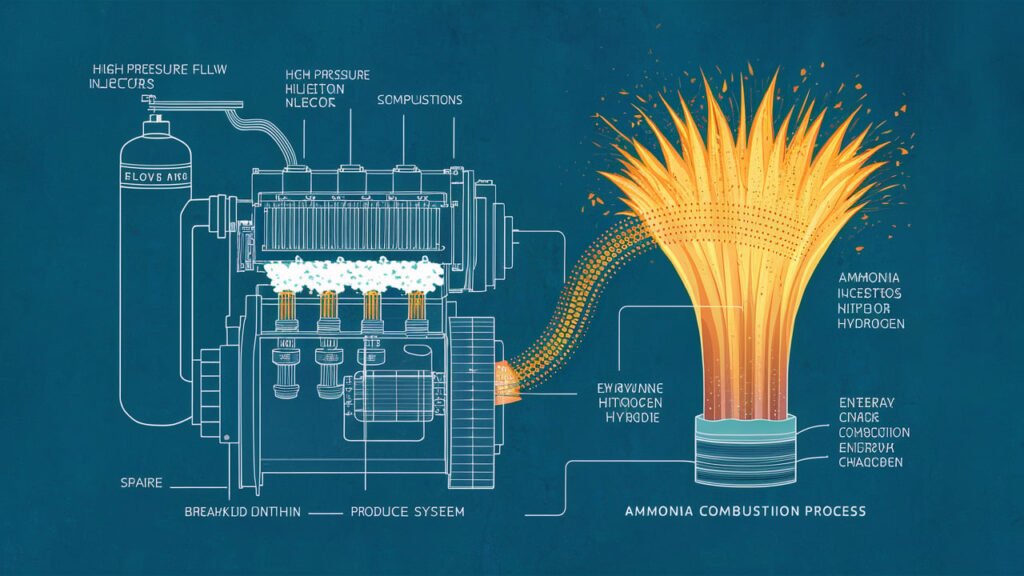

Fuel is then injected directly into the combustion chamber, igniting due to the high temperature. This process, known as compression ignition, generates an explosion that pushes the piston down, like the petrol engine. An ammonia engine can operate using principles from either petrol or diesel engines but uses ammonia as the primary fuel. Ammonia is introduced into the combustion chamber, often with a small amount of another fuel like hydrogen to aid ignition. When ammonia is burned, it breaks down into nitrogen and hydrogen, which then combusts to produce energy. This process involves drawing air into the cylinder, compressing it, and mixing it with ammonia. The mixture is ignited, either by a spark (in a modified petrol engine) or by compression (in a modified diesel engine). The resulting combustion pushes the piston down, driving the crankshaft. The exhaust gases, mainly nitrogen and water vapor, are expelled through the exhaust system.

Thus, ammonia engines can adapt the mechanisms of traditional internal combustion engines with modifications to handle ammonia’s unique properties, providing a potential alternative fuel source.

Current application

Ammonia engines are currently being applied in several experimental and pilot projects aimed at reducing carbon emissions. The maritime industry is at the forefront of this development, with companies like MAN Energy Solutions and Wärtsilä developing ammonia-powered engines for ships. These engines are being tested for their ability to meet stringent emission regulations while providing reliable performance. Additionally, ammonia is being explored as a fuel for stationary power generation systems, where it can be used in modified internal combustion engines or fuel cells. These applications highlight ammonia’s potential as a sustainable fuel alternative, capable of reducing greenhouse gas emissions and supporting the transition to cleaner energy solutions in various sectors.

New features

- Advanced Catalytic Converters: Here, advanced catalytic converters will be used to minimize nitrogen oxide (NOx) emissions, making ammonia combustion cleaner.

- Dual-Fuel Capability: It is designed so that it will operate on a mixture of ammonia and other fuels like hydrogen or gasoline, providing flexibility and ease of transition from conventional fuels.

- High-Pressure Fuel Injection: High-pressure fuel injection systems will be used to ensure efficient combustion and performance.

- Ammonia-Specific Sensors: Sensors and control systems specifically are designed for ammonia, ensuring optimal performance and safety.

- Integrated Safety Systems: Advanced safety mechanisms will be used for handling ammonia’s toxic and corrosive properties, ensuring safe storage, transportation, and combustion.

- Retrofitting Capability: Existing internal combustion engines could be retrofitted with minimal modifications, allowing for a viable option in transitioning existing fleets.

- Enhanced Thermal Efficiency: Improved thermal efficiency compared to traditional engines, thanks to optimized combustion processes for ammonia.

Advantages

The ammonia engine presents a promising alternative to traditional fossil fuel engines. Its innovative design and use of ammonia as a primary fuel offer several significant advantages over conventional energy sources. Here are some of the key benefits of ammonia engines:

- Low Carbon Footprint: It will significantly reduce carbon emissions compared to fossil fuel engines.

- Renewable Fuel Source: It can be produced from renewable energy sources like wind, solar, and hydroelectric power.

- High Energy Density: It will offer substantial energy storage and delivery, beneficial for long-haul transportation and industrial uses.

- Versatile Applications: Will be suitable for marine transportation, heavy-duty trucks, power generation, and industrial machinery.

- Cost-Effective Production: Ammonia is already widely produced for industrial use, making it readily available and economical as a fuel source.

- Energy Independence: Will reduce reliance on imported fossil fuels, enhancing energy security.

- Existing Infrastructure Utilization: Compatible with current LNG storage and transport infrastructure, reducing the need for new investments.

- Reduced NOx Emissions: Modern ammonia engines are equipped to reduce NOx emissions effectively, contributing to cleaner air.

Disadvantages

- Toxicity and Corrosiveness: Ammonia is toxic and can be corrosive, posing significant safety risks during handling, storage, and transportation. Leaks can be dangerous to both human health and the environment.

- Storage and Infrastructure Challenges: Existing infrastructure for ammonia storage and distribution is not as widespread as for traditional fuels, necessitating significant investments in new infrastructure.

- Lower Energy Density Compared to Some Fuels: Ammonia has a lower energy density than traditional fossil fuels like gasoline and diesel, potentially leading to reduced range and efficiency for vehicles.

- Combustion Challenges: Ammonia’s combustion properties are not as favorable as those of traditional fuels. It has a higher ignition temperature and slower flame speed, which can result in lower engine performance and efficiency.

- NOx Emissions: While ammonia engines can reduce carbon emissions, they can still produce nitrogen oxides (NOx), which are harmful pollutants. Advanced catalytic converters are necessary to mitigate these emissions, adding complexity and cost.

- Energy-Intensive Production: The production of ammonia, especially through conventional methods, is energy-intensive and currently relies heavily on fossil fuels. This can offset some of the environmental benefits unless renewable energy sources are used.

- High Initial Costs: Developing and implementing ammonia engines and the necessary infrastructure can involve high initial costs, making it a less attractive option in the short term.

Future Predictions

Ammonia engines are predicted to play a significant role in the future of sustainable energy, particularly in the transportation sector. The maritime industry is expected to see widespread adoption of ammonia-powered ships due to strict emissions regulations and a global push for cleaner energy. Companies like Toyota are at the forefront, developing ammonia-powered vehicle prototypes and conducting research to assess the viability of ammonia in cars. This development highlights the growing interest and investment in ammonia technology, aiming to provide a cleaner alternative to conventional fuels in the automotive industry.

Technological advancements in fuel storage, combustion processes, and emissions control are expected to improve the efficiency and reliability of ammonia engines, making them more competitive with traditional fuels. Ammonia can also be produced using renewable energy sources like wind and solar power, creating a sustainable fuel cycle that integrates seamlessly with broader renewable energy systems.

Beyond the transportation sector, ammonia engines hold promise for power generation. They could provide a cleaner alternative to fossil fuels in power plants. As the technology matures and economies of scale are achieved, the cost of producing and using ammonia as a fuel is expected to decrease, enhancing its economic viability. Government policies and international agreements aimed at reducing carbon emissions and promoting sustainable fuels will likely support the adoption of ammonia engines, driving the transition to ammonia as a mainstream fuel.

Moreover, ammonia engines may find applications in heavy-duty transportation, agriculture, and industrial processes, further expanding their impact on global emissions reduction. The future looks promising for ammonia as a versatile and sustainable energy source, with significant potential to revolutionize various sectors and contribute to a cleaner, greener planet.

Is it Actually the end of EVs?

The rise of ammonia engines does not directly signal the end of electric vehicles (EVs). Instead, it indicates the growing potential of ammonia engines in future applications. Both technologies have their unique advantages and potential applications, and they can coexist to address different aspects of sustainable transportation.

EVs, which run on electricity stored in batteries, are highly efficient, produce zero tailpipe emissions, and are well-suited for urban transportation and short to medium distances. They have gained significant popularity and investment, with continuous advancements in battery technology improving their range and reducing costs.

Ammonia engines, on the other hand, offer a viable solution for sectors where EVs might face limitations, such as maritime shipping, long-haul trucking, and heavy industry. Ammonia can be stored and transported more easily than hydrogen and can be produced using renewable energy sources. It provides an alternative pathway to decarbonize sectors that are challenging for battery-electric solutions due to energy density and refueling infrastructure requirements. Moreover, companies like Toyota and China’s Guangzhou Automobile Group Co. (GAC) are heavily investing in ammonia technology, aiming to increase efficiency and environmental friendliness while reducing costs. This investment may shift some focus from EVs to ammonia-based vehicles.

In summary, while ammonia engines present exciting possibilities for sustainable energy, they complement rather than replace EVs. The future of transportation will likely involve a mix of technologies, including EVs, ammonia engines, hydrogen fuel cells, and other innovations, each playing a role in reducing carbon emissions and promoting sustainability across different applications and industries.